While the 2025 harvest was largely defined by material variability; for many the operational focus for 2026 and beyond is set on energy efficiency and decarbonisation, aligning the UK processing sector with a lower-carbon, more sustainable future.

This shift is about more than compliance; it’s a strategic opportunity. As we advance towards greater sustainability, optimising power usage becomes increasingly important for managing costs and financial resilience. For UK feed mills, flour mills, and biomass plants, managing this transition requires investment priorities to focus on power-to-tonnage efficiency as well as throughput.

While material handling and final product formation are crucial, they are often the biggest energy consumers. Any inefficiency in these steps directly translates into higher operational expenditure and a larger environmental footprint.

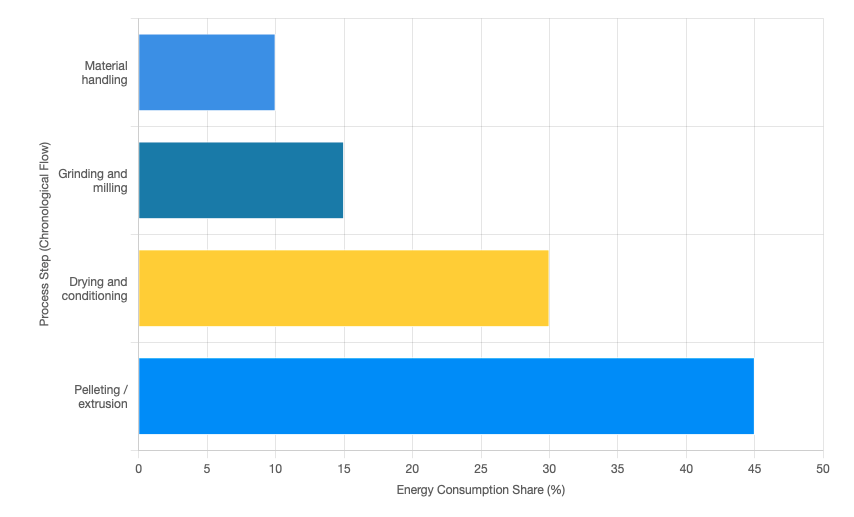

Based on industry estimates, a typical grain UK processing facility’s energy consumption breaks down across key operational areas:

The largest single user of energy is typically the final stage, particularly pelleting, where enormous mechanical forces are applied. If an older pellet press is running slightly off-spec, the resulting energy waste can be substantial.

The financial incentive to improve operational efficiency has never been stronger. High energy costs mean strategic investment in efficient machinery now offers a rapid return on investment (ROI) via reduced utility bills.

Furthermore, future UK government policy is likely to include mandatory carbon intensity reporting for key sectors, demanding granular data on power consumption per tonne of finished product. Processors who fail to invest in efficiency risk higher “carbon taxes” and exclusion from major retailer/customer contracts that demand transparently low-carbon supply chains.

Ultimately, the goal is to turn variable raw inputs into consistent outputs while dramatically reducing the energy cost of that transformation. This is where we can help, as our focus is on delivering systems that maximise usable output while minimising power consumption.

For example, by optimising die selection, roller adjustment, and overall machine design, the Kahl pellet presses we supply achieve an industry-leading power-to-tonnage ratio. Upgrading from older machines can result in double-digit percentage drops in energy use for the pelleting process alone.

In addition, our consultancy services include analysis of existing plant to identify the most significant energy drains, providing advice on upgrades such as Installing Variable Frequency Drives (VFDs) on motors for conveyors and fans, optimising drying and cooling cycles, and providing precise system control to eliminate unnecessary power use during partial load periods.

Please get in touch if you would like to find out more.